LVC Adjustments and Packs in Series

With more and more RTR kits coming out that require 2

packs to be run in series I thought it’s time to give some info regarding these

setups. Running 2 packs in series is not a good setup and is used because it’s

more convenient as it’s easier to get purchase lower voltage packs and put them

in series. The reason why this setup isn’t very good is because the packs will

discharge down to different levels. This is due to the flow of current, the

current from one pack must flow ‘through’ the second pack meaning that the

current sees virtually double the resistance of the first pack. As you read below about the ESC cutoff, the

pack with the highest resistance will drain the least. The ideal setup would be

to run 1 pack at the proper voltage instead of 2 packs in series to get the

desired voltage. This is why we offer 6S packs that fit in

the Arrma 2018 battery trays as Arrma allows the use of one

6S pack instead of two 3S packs.

If you

are running a Traxxas kit or other kit that doesn’t allow for one

pack to be used you need to make sure the low voltage cutoff (LVC) in

your ESC is set high enough for the lowest of the 2 packs to not have the cells

be discharged down to low. Discharging packs down too low under load will

decrease cycle life and increase the chance of cell damage. Once you have hit

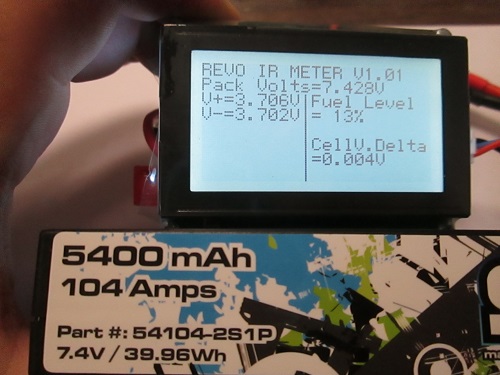

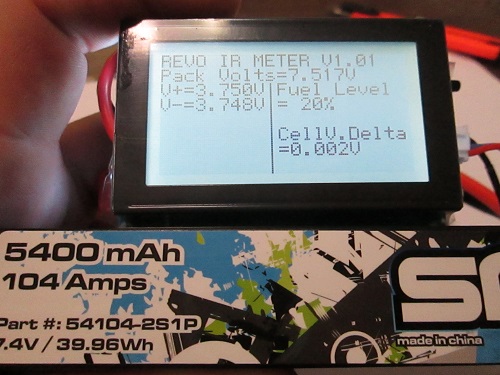

the low voltage cutoff take the packs out and look at the cell

voltages. If they are below 3.6v per cell you need to increase

your cutoff. If your ESC doesn’t have an adjustable cutoff or

it’s already at the highest setting then you need to consider running a LiPo Alarm

which can be attached to the pack and connected to the packs balance connector.

An important aspect

of running 2 packs in series that is often overlooked is to swap the packs

every run. That is to have each pack run on the ESC negative lead and positive

lead alternatively. As mentioned above, one of the packs is basically solicited

twice as much as the other, by alternating which is seeing twice the work load

every run, you are using the packs equally. We recommend keeping packs in pairs

when used in series, and by marking each pair 1A-1B, 2A-2B, etc. it is easy to

keep track of which pack has been used on which ‘side’ every run.

If you are

running 2 packs in series and one gets damaged it’s best to replace both packs

as if you take a new pack and run it with one that has some cycles put through

it you will have an even greater difference in discharge between the packs. As

a pack gets cycled the mAh drops and the resistance will increase. A

new pack with higher mAh and lower resistance will not discharge down

as low as the older pack.

The low voltage cutoffs on ESCs aren’t very accurate as there are a few things that will impact when they will cutoff. The resistance of the pack and the rest of the system will have an impact on how much voltage drop the ESC will have. For example you have 2 different set of packs with the same mAh but one set has 7mOhms of resistance per cell and the other set has 1.8 mOhms of resistance per cell the set with the higher resistance will have more voltage drop under load. This means the cutoff will kick in earlier and the cells won’t be discharged down as low. If running packs in cool/cold weather they will cutoff earlier then running them in warm/hot weather as the packs resistance is higher when they are cool/cold. If you are running on a low traction surface like concrete or asphalt your packs will discharge down more before the cutoff kicks in. This is due to less amps being pulled so the voltage drop is less which means the packs will discharge more before the cutoff kicks in. The opposite is running in grass or sticky mud you will pull more amps and the voltage drop will be higher so you will discharge the pack down less. This is why it’s important to have your cutoff set and adjusted based on the conditions you run in. As mentioned above the best way to check and make sure your cutoff is cutting in at the proper level so your packs don’t get dis charged down to low is to check the cell voltages as soon as the cutoff kicks in you want the cells to be at 3.6v or above.

There are no products to list in this category.